Pland Stainless manufacture a broad range of stainless steel products and relies heavily on a team of skilled and semi-skilled employees. They have a workforce of 50, mainly involved in production and are constantly on the lookout for individuals of varying skill levels, to join a like-minded team. So, if you’re considering a career in a busy manufacturing environment, get an insight into Pland by reading our Lifelong Skills series….

Pland is a busy and growing, Leeds-based manufacturer of commercial stainless-steel products. They put part of their success down to their employee retention record, which is well above average with many employees achieving over 30 years of service with the business. Pland employs traditional skilled tradesmen and regularly recruits apprentices to learn and continue these skills. It’s this experience and knowledge that gives them a competitive advantage, especially with such a large range of specialist products and a growing proportion of bespoke designs that they create and manufacture.

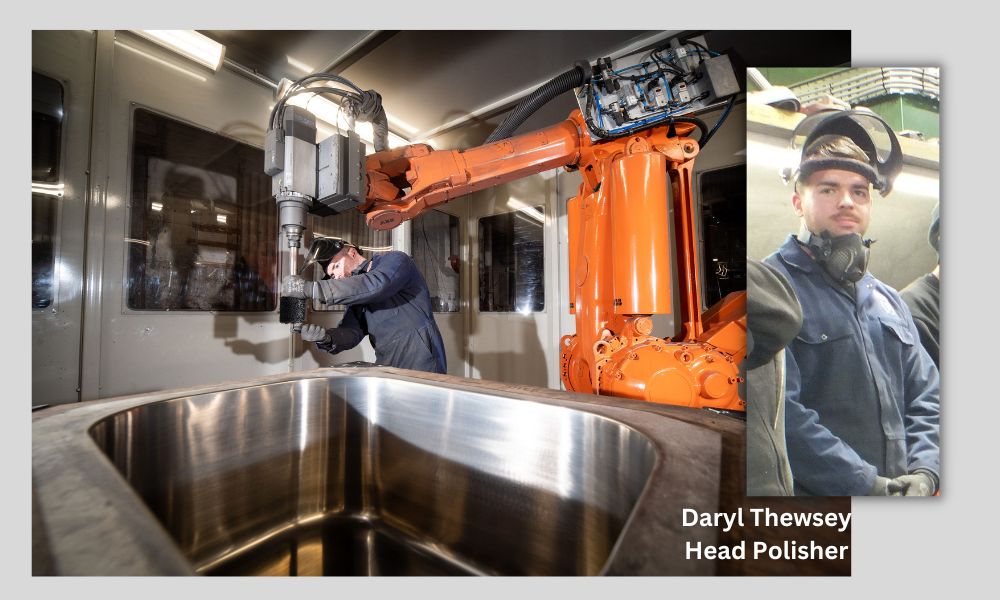

This month we talked with the Polishing team at Pland. It’s a growing team of eight individuals and it is the largest production team in the factory, as most products need to be polished as the final process before dispatch.

Stainless steel products go through several processes as part of their creation, from laser cutting, and fabrication, to brake press, and welding and the final product will require polishing to a specified finish. The polishers also provide a quality check of the product as they have a keen eye for detail to complete the task.

Primarily, a polisher takes a product in this final process and uses a number of different tools to polish out the welding marks and remove any sharp edges. They use mechanical polishing wheels and different levels of abrasives to remove burn marks from the welding process and hammer marks from any planishing too. Various tools, like electric grinders, can be used to grind flat any seam welds and then overhead spindles, sanding belts and hand tools ensure grind marks are removed in readiness for a finished fine polish.

The end product needs to be smooth and depending on the customer’s requirement, they create the finish, whether that be spotless, satin, high gloss or mirror, the latter taking more time and therefore at a higher cost.

The variety in the work is down to the broad range of products offered by Pland, from champagne troughs to healthcare endoscopy sinks, and body trays to gas kitchen hobs. Some take 15 minutes to polish, some take over a day, depending on the size and complexity of the product, any pin holes or porosity, and each one has its own challenge according to Head Polisher, Daryl Thewsey, who has been polishing at Pland for 8 years.

“To be a good polisher, which is a semi-skilled role, you need to see each product as a challenge and have a desire to achieve perfection. We train many new recruits on-site and within a few years they can become competent polishers, but to be good, and have the ability to tackle any product, it takes around 5 years, and they have to have the right frame of mind. I suppose like any trade it takes time and patience.” Said Daryl

It is not the first labour-intensive role that Daryl has done in his career. He started work on leaving school as a roofer, then a stone mason, so whilst the polishing role is different again, he is no stranger to a hands-on physical job.

The polishing team at Pland has on-the-job training and even with Daryl’s experience he explains that they are constantly learning as new products are introduced and new technologies implemented. The team are of a range of ages. Daryl is in his early 30’s, but overall, the team, currently all men, are aged between 21 and 50 so they vary in both age and experience.

According to Daryl, “Another great part of the job is the team of people you work with each shift. It’s hard work, we have a lot to get through, but it’s great banter too and with everyone having different levels of experience, we all help each other out.”

Business is growing at Pland and so the workload for the polishing team is huge as all products need some level of finishing. The business has just commenced with a second shift to accommodate the increased demand and is looking to recruit further polishers to prevent polishing from becoming a bottleneck in the production process.

Pland has recently invested in a robot polisher too which is assisting the polishing team with the workload and taking some of the simpler and monotonous jobs away from the team. Again, it’s a new skill that the polishing team must learn, setting up the robot to polish a new product.

Check out their website at www.plandstainless.co.uk or contact Pland Stainless on tel: 0113 263 4184. If you’d like to apply for a polishing role, please email DJohnson@plandstainless.co.uk

Back to all News

Get in touch

Stay in touch

Lower Wortley Ring Road, Leeds, LS12 6AA

+44 (0) 113 263 4184

+44 (0) 113 231 0560

Monday - Thursday 9am - 5pm

Friday 9am - 4.30pm

© Copyright Pland Stainless Ltd 2021. All rights reserved. | Conditions of sale | Privacy Policy | Environmental statement

Registered Company Number: 4008116 | VAT Number: GB 747 1555 18